Foreword Public Safety Industry Standard of the People's Republic of China Fire thermal imaging camera Firefighting infrared camera GA/T 635-2006 Distribution Department: Ministry of Public Security Published: August 29, 2006 Effective date: January 1, 2007  This standard was proposed by the Ministry of Public Security Fire Department. This standard is under the jurisdiction of the Fifth Technical Committee of the National Fire Protection Standardization Technical Committee. This standard was drafted by the Ministry of Public Security, Shanghai Institute of Fire Protection, Guangzhou Special Power Infrared Technology Co., Ltd. The main drafters of this standard: Shen Jianmin, Zhou Weiquan, Wu Yigang, Wu Tao, Zhang Yan, and Hu Bin. 1 range This standard specifies the terms and definitions, structures and classifications, models, technical requirements, test methods, inspection rules, markings, packaging and transportation of infrared thermal imagers for firefighting purposes. This standard is applicable to infrared thermal imagers (hereinafter referred to as thermal imagers) used in fire-fighting and rescue operations, emergency rescue operations, and fire protection supervision personnel's use in fire inspections. 2 Firefighting Infrared Thermal Imager Normative References The clauses in the following documents have been adopted as references to this standard. For dated references, subsequent amendments (not including errata content) or revisions do not apply to this standard. However, parties that have reached an agreement based on this standard are encouraged to study whether the latest versions of these documents can be used. For undated references, the latest version is applicable to this standard. GB/T 191 - 2000 packaging, storage and transportation logo ( eqv ISO 780 : 1997 ) GB/T 2423.1 - 2001 Environmental testing for electric and electronic products Part 2 : Test methods Test A : Low temperature ( idt IEC 60068-2-1 : 1990 ) GB/T 2423.2 - 2001 Environmental testing for electric and electronic products Part 2 : Test methods Test B : High temperature ( idt IEC 60068-2-2 : 1974 ) GB/T 2423.3 - 1993 Basic environmental test procedures for electric and electronic products Test Ca : Constant moisture heat test method ( eqv IEC 60068-2-3 : 1984 ) GB/T 2423.5 - 1995 Environmental testing for electric and electronic products Part 2 : Test methods Test Ea and Guidelines: Impact ( idt IEC 60068-2-27 : 1987 ) GB / T 2423.10 - 1995 Environmental testing for electric and electronic products - Part 2: Test methods Test Fc and guidance: vibration (sine) (idt IEC 60068-2-6: 1982) GB 4208 - 1993 Enclosure protection class ( IP code) ( eqv IEC 529 : 1989 ) GB/T 15464 - 1995 General Specifications for Instrumentation Packaging JB/T 9329 - 1999 Basic environmental conditions and test methods for instrumentation, transport, storage and transportation 3 Terms and Definitions The following terms and definitions apply to this standard. 3.1 Thermal Camera infrared camera It refers to the device that converts infrared radiation from the surface of an object into a distinguishable image signal through an infrared optical system, an infrared detector, and an electronic processing system. For thermal imagers that require a quantitative measurement of the surface temperature of an object, grayscale images are generally required to be pseudo-color coded to improve the intuitiveness of the temperature indication. 3.2 Signal to noise ratio The ratio between the peak -to- peak value of the signal voltage and the root mean square value of the noise voltage during normal operation of the thermal imager . 3.3 Noise equivalent temperature difference noise equation temperature difference ( NETD ) Observe a low spatial frequency circular or square target with a thermal imager. When the signal-to-noise ratio ( S/N ) of the video signal is 1 , the equivalent temperature difference between the target and the background is also referred to as NETD . NETD is an objective parameter for evaluating the thermal imaging camera's sensitive target detection process and noise size. 3.4 Spatial resolution spatial resolution The thermal imager's ability to resolve geometric details of the object's space. It relates to the size of the infrared detector pixel used, the focal length and image quality of the optical system, and the bandwidth of the signal processing circuit. It can also be expressed by detector cell angle ( DAS ) or instantaneous field of view. This parameter is usually approximated by the following formula: Spatial Resolution = [2 × π × Horizontal Field of View Angle (°) ] / ( 360 ° × Horizontal Pixels). 3.5 infrared image metadata infrared array size Thermal Imager The number of pixels that can be divided by the detector. When using a staring focal plane infrared detector, it is the number of pixels in the detector. 3.6 Temperature tolerance error excepted of temperature The maximum temperature error allowed in the maximum temperature range. It is generally called "temperature measurement accuracy." 3.7 Measurement range The maximum temperature range over which the camera can perform effective measurements within the allowable temperature error range, which can be extended optically or electronically. 3.8 Temperature drift temperature drift The amount of temperature drift caused by changes in ambient temperature. 3.9 sampling frame rate Collect the reciprocal of the time interval ( s ) for two frames of image . 3.11 working band spectral response The infrared wavelength range that the camera responds to. 3.12 Operating temperature operating temperature Thermal imager outside temperature during working hours. 3.13 rescue camera thermal camera of salvation It is usually a handheld thermal imager that requires battery power, an infrared image display, and a rough temperature indication. It is required to guide firefighters to rescue personnel, find fire sources, and prevent firefighters from straying into high-temperature dangerous areas under harsh smoke and high-temperature fire scene conditions. 3.14 detection camera thermal image of detection A portable device used for fire inspections, usually as a fire protection supervisor. Requirements can be in the thermal imager with image display, temperature analysis and image storage capabilities. The accuracy of temperature measurement is required to be high, and the temperature image information of the measured target can be given in real time. 4 Structure classification 4.1 Structure The thermal imager consists of a lens assembly, a movement assembly, a display device, and a power supply. 4.2 Classification The thermal imager is divided into a salvage thermal imager and a detection thermal imager according to its application mode. 5 models Marking example: HRYXJ-A indicates the rescue type A firefighting infrared camera. 6 Technical Requirements 6.1 Basic parameters 6.1.1 Sample frame rate The thermal imager sampling frame rate is not less than 25 frames /s . 6.1.2 Probe Types Thermography detectors should use uncooled focal plane detectors. 6.1.3 Working Band Imager operating band should be within 14 μ m 8 μ m ~ of. 6.1.4 Use Environment Requirements of Infrared Thermal Imager Thermal imager use environment requirements are as follows: a ) Working environment temperature: - 10 °C ~ 50 °C; b ) Specific operating ambient temperature: >50 °C and ≤ 260 °C; c ) Working environment humidity: ≤ 85 % (at 40 °C); d ) storage environment temperature: - 30 °C ~ 60 °C; e ) Storage environment humidity: ≤ 93 % (at 40 °C). 6.2 Functional requirements The camera should have the following features: a ) Display function: In the infrared mode, it has three display modes: white heat, black heat, and false color. It has temperature measurement value and battery consumption proportion display function; b ) Image freeze function; (The salvage camera may not have) c ) Image storage function; (Aid-type thermal imager may not be available) d ) Image noise reduction; e ) Really restore the captured thermal image function; (The salvage thermal imager may not be available) f ) Operation prompt function: Chinese operation menu or prompt function; (The rescue thermal imager may not be available) g ) Correction function: After the target distance, target emissivity, ambient temperature, and relative humidity are input, the effects of corrected atmospheric transmittance and target surface emissivity on the measurement result are automatically calculated. (The salvage camera may not have) 6.3 Performance Requirements 6.3.1 Appearance The shell of the host and its various accessories should not appear obvious scratches, dents, deformation, paint stripping, and the shell should be clean and free of stains. Decorative text, numbers, symbols and signs should be correct, easy to identify, and clear. 6.3.2 Quality The quality of the camera should not exceed 3kg (including batteries). 6.3.3 Spatial resolution The spatial resolution of the detection thermal imager should not exceed 2.5 mrad , and the spatial resolution of the rescue thermal imager should be ( 3 to 4 ) mrad . 6.3.4 Noise Equivalent Temperature Difference ( NETD ) When the ambient temperature is 23 °C ± 5 °C, the focal length is 50mm , and the F number is 1 , the NETD should not be greater than 0.2K . 6.3.5 Temperature Range The temperature range of the thermal imager should be in the range of -20 °C to +500 °C. 6.3.6 Allowable error The salvage camera should not be more than ± 10 °C or ± 10 % of the measured value (°C) ; the detection camera should not be more than ± 2 °C or ± 2 % of the measured value (°C) . 6.3.7 Temperature drift The thermal imager shall be tested in accordance with the method of 7.5.7 . When working at different ambient temperatures, the temperature measurement drift shall not be greater than 2 °C or the blackbody set temperature shall be 2 %. 6.3.8 Continuous stable working time The thermal imager is tested according to the method of 7.5.8 , and the continuous stable working time should not be less than 2h . 6.3.9 Specific ambient temperature duration The salvaging thermal imager's continuous working time at a specific ambient temperature is as follows: a ) 80 °C, 30min ; b ) At 120 °C, 10min ; c ) 5 min at 260 °C . 6.3.10 Anti-drop performance After the camera has been dropped from a height of 1m from a height of 1m in one of the three directions ( X/Y/Z ) , the thermal imager function shall be checked and the requirements of 6.2 shall be complied with (the handle shall be damaged and the replacement shall be permitted). 6.3.11 Shell protection The salvage thermal imager shall meet the requirements of IP67 in the enclosure class of GB 4208 - 1993 ; the detection thermal imager shall meet the requirements of IP54 in the enclosure class of GB 4208 - 1993 . 6.3.12 Environmental Adaptability 6.3.12.1 Thermal properties After performing the damp heat test as specified in 7.5.12.1 , the function of the thermal imager shall be in accordance with 6.2 . 6.3.12.2 High Temperature Performance After high temperature test in accordance with the provisions of 7.5.12.2, check the thermal imager functions, it should comply with the provisions of 6.2. 6.3.12.3 High temperature storage performance After performing the high-temperature storage test according to 7.5.12.3 , the function of the thermal imager shall be in accordance with 6.2 . 6.3.12.4 Low temperature performance After the low-temperature test in accordance with the provisions of 7.5.12.4 of work, check the thermal imager functions, it should comply with the provisions of 6.2. 6.3.12.5 Low temperature storage performance After performing the low-temperature storage test according to the provisions of 7.5.12.5 , the function of the thermal imager shall be in accordance with 6.2 . 6.3.12.6 Vibration resistance After performing the vibration test as specified in 7.5.12.6 , the function of the thermal imager shall be in accordance with 6.2 . 6.3.12.7 Impact resistance After performing the impact test in accordance with 7.5.12.7 , the function of the thermal imager shall be in accordance with 6.2 . 6.3.13 Simulating fire scene imaging performance The salvaging thermal imager should clearly observe the image of the target in heavy smoke. 7 test methods 7.1 Equipment Instrument Error The allowable error or accuracy of the equipment used for testing shall not be greater than 1/3 of the allowable error , and the selection and periodicity verification shall be conducted according to the relevant national measurement regulations. 7.2 Laboratory Requirements Laboratory interior lighting should not significantly affect the image quality. The laboratory temperature is 23 °C ± 5 °C and the relative humidity is 40 % to 80 %, which meets the cleaning requirements. 7.3 Experimental Equipment 7.3.1 NETD Test Equipment a ) Standard temperature difference blackbody Temperature accuracy: ± 0.03K ; Emissivity: >0.95 ; Temperature uniformity: ± 0.01 °C; Temperature difference source emission area: meet the experimental requirements; The maximum available aperture area: to meet the experimental requirements. b ) Optical platform c

Material: SS304, SS316

Weave type: Plain weave, Twilled weave, Dutch weave

Features: Corrosion-resisting, Wear-resisting

Uses:Mainly used for filtering and sieving, extensively used in petroleum, chemical industry, enviroment protection,

mine, airspace, paper-making, electronic, metallurgy etc.

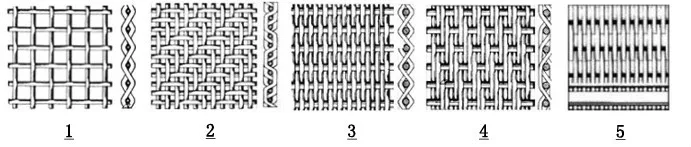

Weave type explanation

1. Plain Weave: also called tabby weave, linen weav or taffeta weave, is the most basic type of weaves.

In plain weave, the warp and weft are aligned so they form a simple criss-cross pattern. Each weft thread

crosses the warp threads by going over one, then under the next, and so on. The next weft thread goes under

the warp threads that its neighbor went over, and vice versa.

to the right or left, forming a distinct diagonal line. This diagonal line is also known as a wale. A float is the portion of

a yarn that crosses over two or more yarns from the opposite direction. Stainless Steel Series,Stainless Steel Wire Mesh,Stainless Steel Crimped Wire Mesh,Stainless Steel Window Screen Anping Shengjia Hardware Mesh Co.,LTD , https://www.oilshaleshakerscreen.com

2. Twill Weave: In a twill weave, each weft or filling yarn floats across the warp yarns in a progression of interlaces

3. Plain Dutch Weave: similar with plain weave, just the weft and warp wire have different wire diameter and different mesh size.

4. Twill Dutch Weave: similar with twill weave, just the weft and warp wire have different wire diameter and different mesh size.

5. Reversed Dutch Weave: difference from standard Dutch weave lies in the thicker warp wires and less weft wires

"GA/T635-2006" fire-fighting infrared camera

News Related Keywords: No tags.